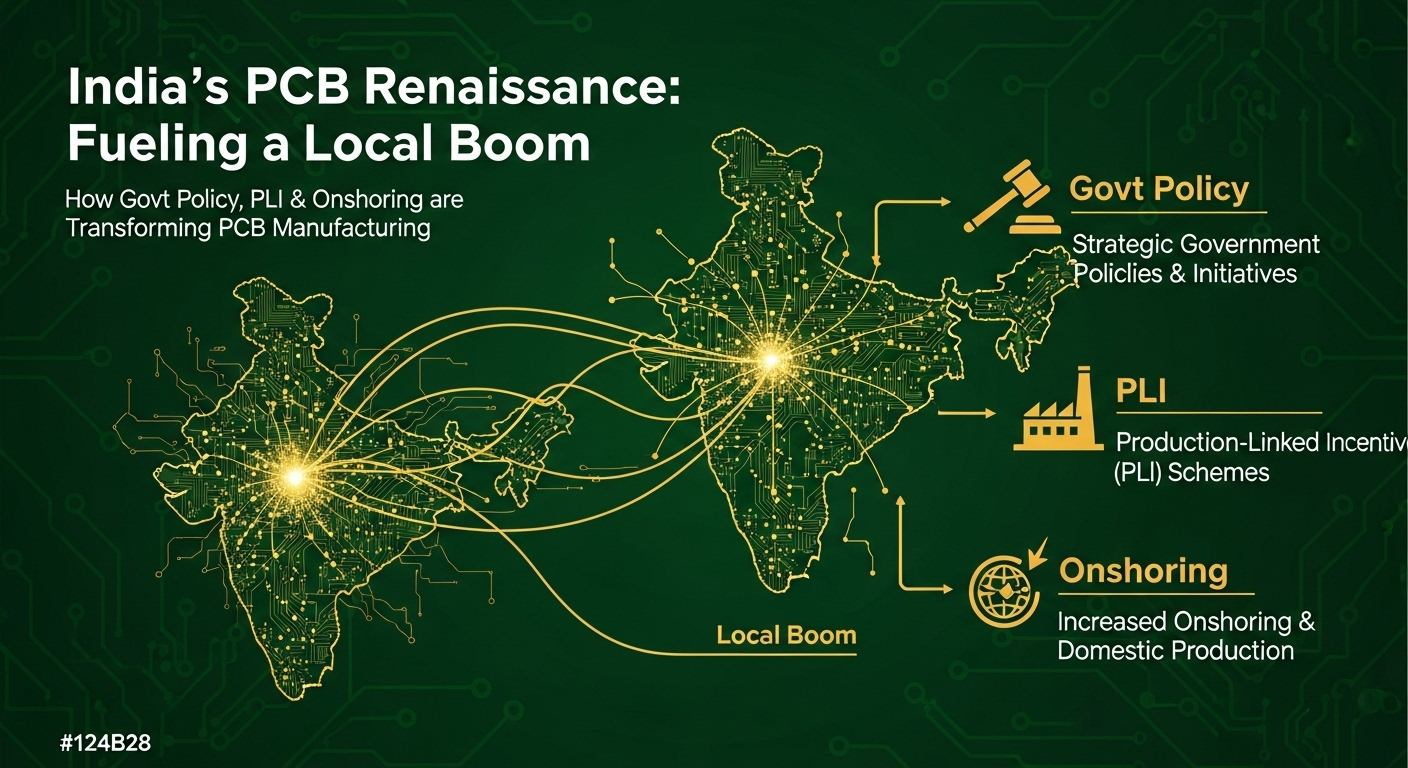

Over the past few years, India has been making bold moves to strengthen its electronics manufacturing sector. Backed by government schemes like PLI (Production Linked Incentives) and a broader push for onshoring critical components, the country is entering what many call a PCB renaissance.

For companies building smartphones, 5G networks, automotive electronics, and IoT devices, this shift means shorter supply chains, reduced import dependency, and greater local availability of advanced printed circuit boards (PCBs).

The Role of PLI and Govt Incentives

The Indian government has announced multiple programs to attract investment and boost electronics production. The PLI scheme, in particular, rewards companies that expand local manufacturing capacity while meeting output and export targets.

Key highlights include:

- Incentives for large-scale electronics manufacturing and component ecosystems

- Special focus on semiconductors, PCBs, and display units

- Support for both domestic players and global companies setting up plants in India

- Integration with “Make in India” and “Digital India” initiatives

This policy-driven growth is already visible. Several international electronics majors have announced plans to establish or expand operations in India, and local companies are scaling up to meet demand.

Why PCB Manufacturing is Critical

PCBs may not get the same attention as semiconductors, but they are just as essential. Every device — from a smartphone to a satellite — relies on them. Without a strong local PCB ecosystem, India’s electronics value chain remains incomplete.

Some reasons why PCBs are central to this ecosystem:

- Base of all electronics: No electronic device functions without a reliable PCB.

- Import dependency: Until recently, a large share of advanced PCBs was imported, mainly from East Asia.

- Time-to-market: Local PCB manufacturing reduces lead times for Indian companies.

- Cost efficiency: Domestic sourcing cuts logistics costs and currency risks.

- Security & supply chain resilience: In critical sectors like defense, space, and telecom, local PCB production improves strategic independence.

Impact on Imports, Supply Chains & Global Partnerships

As India ramps up PCB production, the ripple effects are clear:

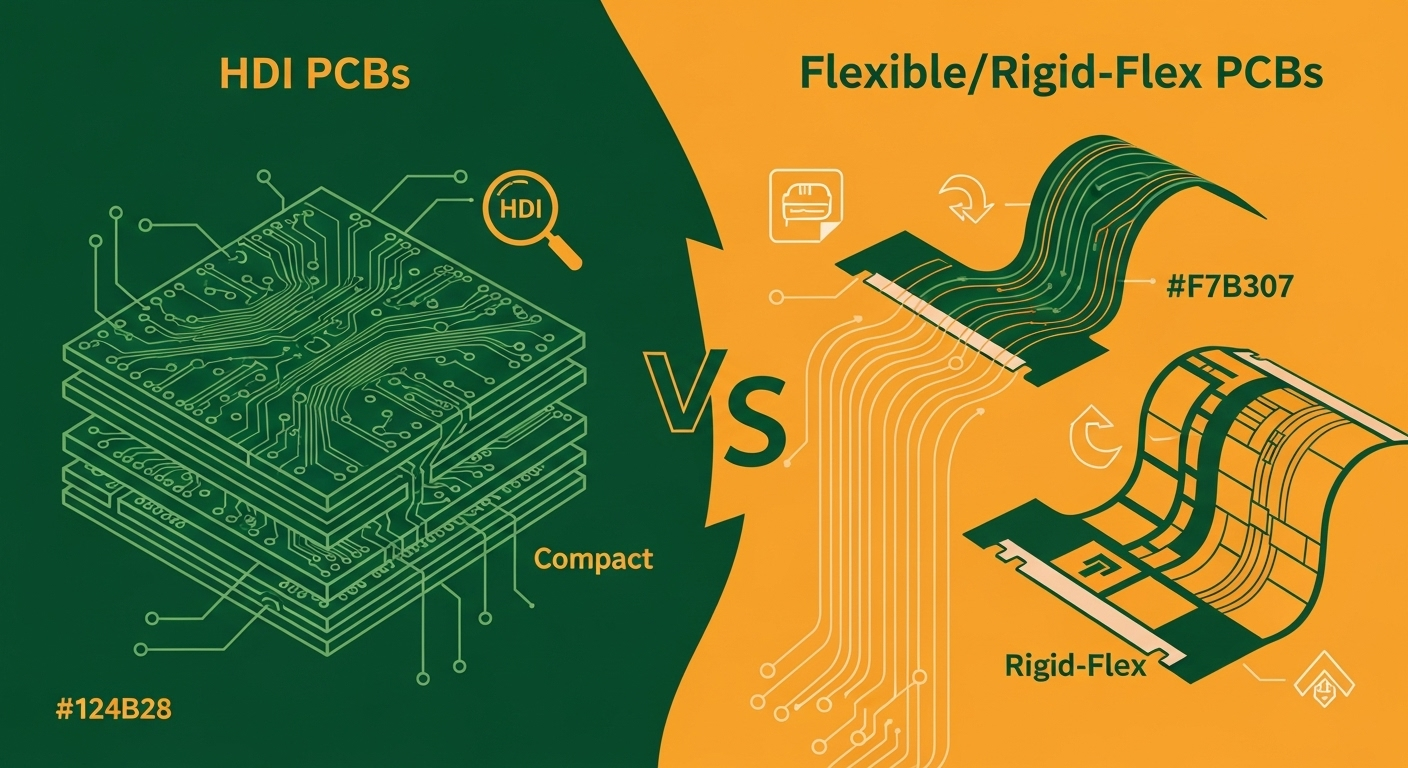

- Reduced Imports: A stronger domestic base reduces reliance on imports, especially for multilayer, HDI, and rigid-flex boards.

- Improved Supply Chains: Local manufacturing ensures faster turnaround and quicker prototyping for startups and OEMs.

- Global Collaboration: With incentives in place, global firms are more open to partnerships, joint ventures, and technology transfers.

- Export Potential: As capacity scales, India can position itself not just as a consumer market but as a global hub for PCB manufacturing.

Where Sulakshana Circuits Fits In

At Sulakshana Circuits Limited (SCL), we see this as both an opportunity and a responsibility. Since 1988, we have been part of India’s journey in electronics manufacturing, providing reliable, high-quality PCBs for industries ranging from telecom and defense to automotive and consumer electronics.

Here’s how we align with this new wave:

- Technology Readiness: From ROHS-compliant boards to ENIG finishes, HDI, and exotic substrates like Rogers, our capabilities match the requirements of next-gen applications.

- Quick Turnaround: Our commitment to on-time delivery supports India’s growing ecosystem of startups and global OEMs who demand faster design-to-production cycles.

- Sustainability: As environmental norms tighten, SCL is actively investing in greener processes and exploring renewable PCB materials for the future.

- Scalability: With decades of experience, we are positioned to scale alongside India’s expanding electronics ecosystem and global supply chain integration.

The Bigger Picture: India as a Global PCB Hub

The next five years could see India become one of the world’s largest electronics manufacturing centers. With demand soaring for 5G devices, EV components, IoT hardware, and medical electronics, the importance of reliable PCB suppliers will only grow.

Companies that invest today in local partnerships and manufacturing capacity will be best placed to benefit from:

- A rapidly growing domestic market

- Strong government support through PLI and related policies

- Opportunities to export to global markets seeking alternatives to single-source supply chains

Conclusion

India’s PCB industry is entering a new era. Backed by PLI schemes, government incentives, and rising demand across sectors, local manufacturing is poised to reduce import dependency and strengthen supply chain resilience.

For innovators, this means faster access to high-quality boards. For manufacturers, it opens the door to global partnerships and exports.

At SCL, we are proud to be part of this transformation. With more than three decades of experience, we continue to adapt, innovate, and deliver PCB solutions that support India’s growing role in the global electronics ecosystem.