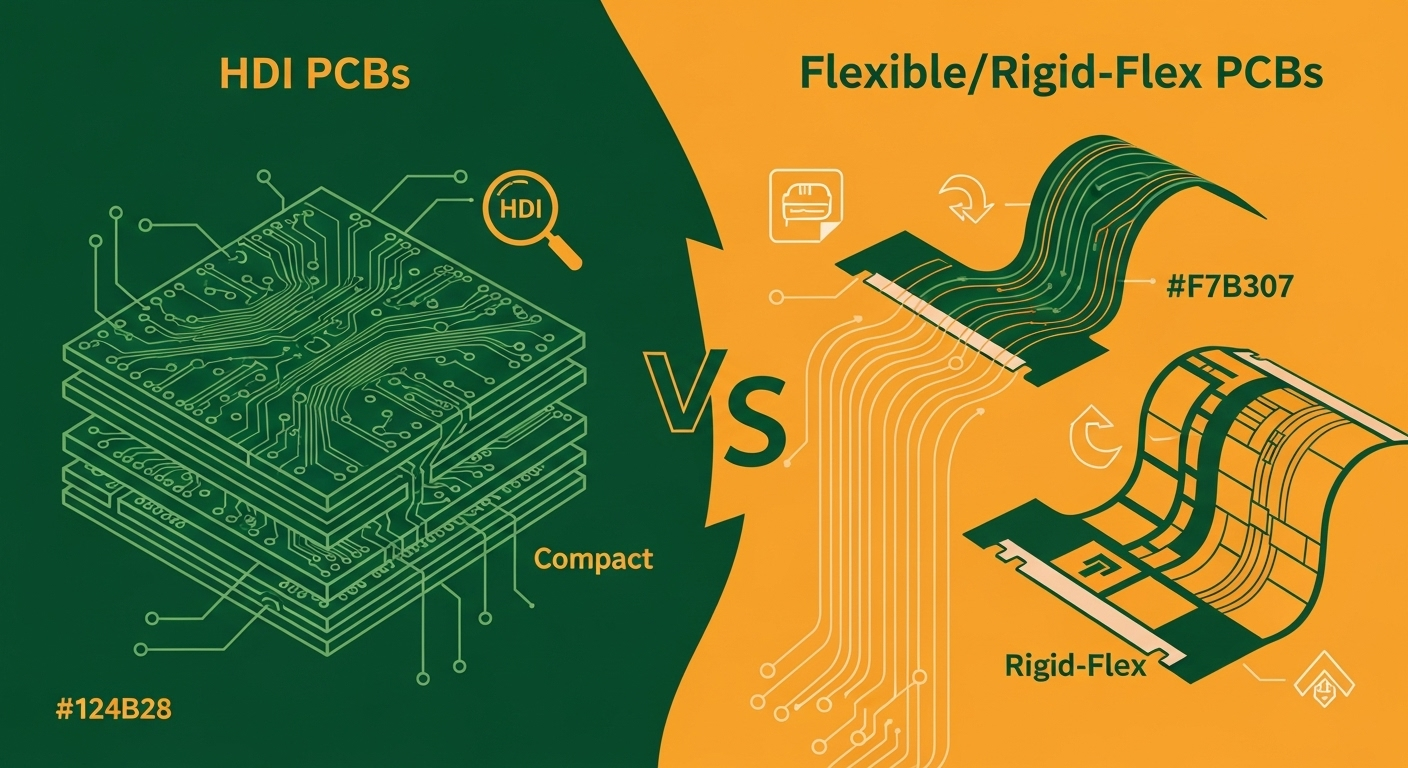

Printed circuit boards (PCBs) form the foundation of every modern electronic product. As devices get smaller, faster, and more feature-packed, traditional PCB designs often fall short. Two technologies that have become especially important in recent years are HDI (High-Density Interconnect) PCBs and flexible or rigid-flex PCBs.

Both serve different purposes, and understanding their strengths is critical when designing products for fast-growing markets like 5G communication, IoT sensors, and wearable devices.

What is an HDI PCB?

An HDI PCB uses advanced manufacturing techniques such as microvias, finer traces, and higher wiring density to pack more functionality into a smaller footprint. This design approach allows engineers to fit complex circuits into compact products without sacrificing performance.

Advantages of HDI PCBs:

- Higher component density for compact designs

- Better signal integrity at high frequencies

- Improved electrical performance with reduced crosstalk

- Ideal for multilayer applications where space is limited

Typical applications: smartphones, 5G routers, tablets, aerospace systems, and high-performance computing boards.

What are Flexible and Rigid-Flex PCBs?

Flexible PCBs are built on materials that can bend, twist, or fold, allowing them to fit into unconventional shapes or moving assemblies. Rigid-flex PCBs combine rigid sections for component mounting with flexible sections that can fold, creating a hybrid design that saves space and reduces connectors.

Advantages of Flexible/Rigid-Flex PCBs:

- Lightweight and thin, making them ideal for compact devices

- Increased reliability due to fewer interconnects and solder joints

- Ability to handle continuous bending and dynamic movement

- Simplified assembly compared to multi-board solutions

Typical applications: wearable devices, medical implants, cameras, automotive electronics, and defense equipment.

HDI vs Flexible/Rigid-Flex: A Practical Comparison

| Feature/Factor | HDI PCB | Flexible/Rigid-Flex PCB |

|---|---|---|

| Size & Density | Very high density, compact multilayer | Moderate density, optimized for form factor |

| Flexibility | Rigid, not bendable | Can bend, twist, and fold |

| Signal Integrity | Excellent for high-speed signals | Good, but design must consider flex movement |

| Durability | Strong under static use | Strong in dynamic or moving environments |

| Cost | Higher than standard PCBs, cost-effective in volume | More expensive due to material and complexity |

| Best Use Cases | 5G devices, computing, aerospace | Wearables, IoT sensors, medical devices |

Which One Fits 5G, Wearables, and IoT?

- 5G Devices

HDI PCBs are the go-to choice. With their ability to handle high-speed signals, reduced loss, and compact design, they are perfectly suited for the tight layouts of 5G smartphones, routers, and small cells. - Wearables

Flexible and rigid-flex PCBs dominate this space. Devices such as fitness trackers, smartwatches, and medical monitoring equipment rely on boards that can bend and survive constant movement. - IoT Sensors

Both technologies have a role here. HDI PCBs are useful for high-performance IoT gateways or compact communication modules, while flexible PCBs are ideal for lightweight, portable sensors deployed in varied environments.

Key Considerations When Choosing

- Space and Size Constraints

If every millimeter matters and your design is dense, HDI may be the better choice. If the product requires bending or folding, flexible PCBs win. - Performance Requirements

For high-speed, high-frequency applications like 5G and data centers, HDI is superior. For wearables or medical devices where comfort and adaptability are more important, flex PCBs are ideal. - Cost Factors

Both HDI and flexible PCBs cost more than standard boards, but the trade-off is improved performance and reliability. Early planning with your PCB manufacturer helps balance cost and design requirements. - Reliability in the Field

HDI PCBs excel in stable, compact environments. Flexible and rigid-flex PCBs are more reliable in applications involving motion, vibration, or irregular shapes.

The Role of PCB Manufacturers in 2025

With India’s growing electronics ecosystem and global demand for advanced boards, choosing the right manufacturing partner is just as important as the technology itself. At Sulakshana Circuits Limited (SCL), we have over three decades of experience in delivering advanced PCB solutions. Our expertise covers ROHS-compliant PCBs, HDI designs, ENIG finishes, and flexible/rigid-flex solutions tailored to high-performance applications.

Whether you’re developing a 5G device, a new IoT solution, or a next-gen wearable, working with an experienced PCB manufacturer ensures your design moves smoothly from prototype to production.

Conclusion

The choice between HDI and flexible/rigid-flex PCBs depends entirely on the product requirements. For high-density, high-speed designs, HDI PCBs provide unmatched performance. For lightweight, compact devices that require flexibility, rigid-flex and flexible PCBs are the way forward.

In 2025 and beyond, both technologies will continue to drive innovation in 5G networks, IoT ecosystems, and wearable electronics. By understanding their differences and working with a trusted manufacturing partner, engineers can build products that are efficient, reliable, and future-ready.